With the news last week that Brimstone Energy has raised $55 million dollars, from investors the likes of Bill Gates, pre-revenue, there is potentially hope for what is the incredibly dangerous situation with embodied carbon within the building industry. Instead of using limestone, Brimstone sources lime from calcium silicate rocks, releasing no CO2. This process also produces a carbon absorbing magnesium species as waste, making Brimstone’s cement net carbon-negative, hence the huge investment in a pre-revenue company. This article will explore what embodied carbon is and why this is such an essential topic for the construction sector to take on and change.

The carbon emissions of a building are typically split into two categories – embodied carbon and operational carbon. Whilst operational carbon refers to the carbon emissions that come from the daily running of a building (e.g. HVAC systems and lighting), embodied carbon encompasses all other aspects of a building’s carbon output. There are four main stages in a building’s life-cycle that impact its embodied carbon emissions: Product, Construction, Embodied Use, and End-Of-Life. Embodied carbon is responsible for an annual 40-50 million tonnes of carbon emissions in the UK alone, an amount approximately equal to Portugal’s annual CO2 emissions, yet is far less discussed than its operational counterpart.

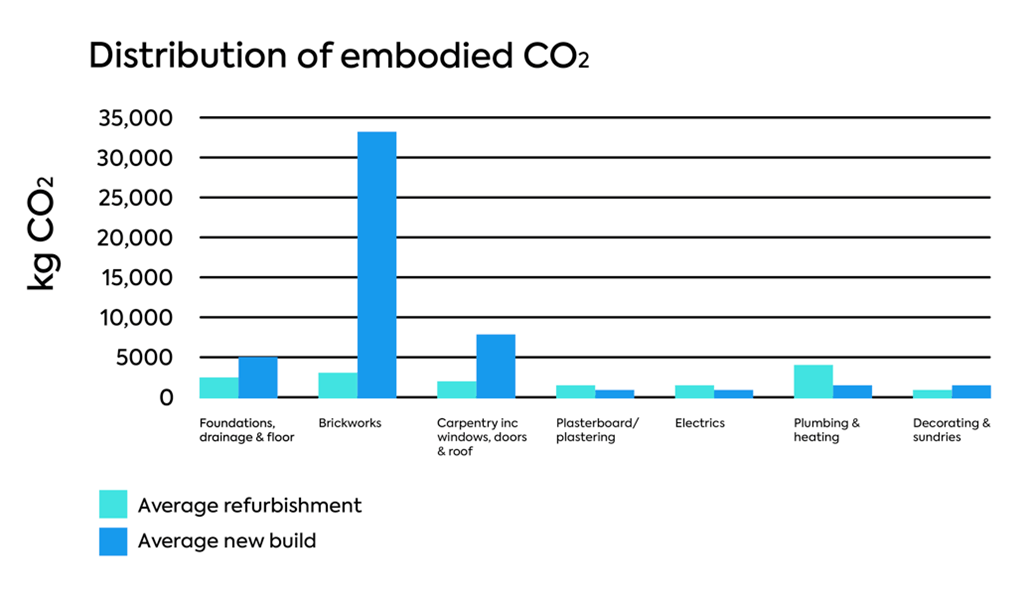

The product and construction stages are the biggest contributors to a building’s emissions, with the product stage sometimes equalling up to 75% of embodied carbon. These stages in the life-cycle of a building largely encompass the sourcing and manufacturing of building products, as well as all aspects of a building’s construction, including transport of materials to and from the site.

The cement industry generates 2.8 billion tonnes of carbon emissions every year, closely followed by steel at 1.85 billion tonnes, and aluminium at 1.1 billion. Transport contributes further to embodied carbon.

Governing bodies are gradually waking up to the dangers of embodied carbon. In January 2022 a new bill, the Carbon Emissions Bill, was proposed by the Environmental Audit Select Committee.

The bill aims to place a stronger focus on the impacts of embodied carbon within the whole life-cycle of a building. As per the bill, developers would have to report the amount of carbon emitted from construction of their projects. Then, between 2023 and 2027, a limit would be placed on the amount of embodied carbon allowed to be emitted, with that limitation reducing over time. Several large scale construction companies, such as the likes of Landsec and Laing O’Rourke, have come out in support of the bill, which is currently at the 1st reading stage of the House of Commons.

One way to significantly cut embodied carbon emissions from the product and construction stages is to use alternative building components. Many current main contenders incorporate wood. Concrete alternative mass-timber, something discussed in a previous article, is becoming more widely used, with over 1300 mass-timber projects in the US according to WoodWorks. There is also Glulam, glued together timber laminates, that can be used as an alternative to steel or concrete.

Although projects like mass-timber and Glulam seem like a viable solution to the embodied carbon produced from traditional construction materials, the situation is far more complicated. Despite the significant drop in emissions that more frequent wood use would cause – only 1 million tonnes compared to the billions from concrete – there is also potential for drastic climate degradation through deforestation. Unless the timber industry takes significant steps to cut deforestation and find sustainable ways of manufacturing timber, its growth within the construction sector will just be another example of passing the buck.

An alternative tool to measure and cut embodied carbon from the product stage are Environmental Product Declarations (EPDs). EPDs are a tool used to account for the environmental impacts of a particular product or material. Several associations offer industry-wide EPDs for various construction materials. EPD calculation tools are an essential part of measuring the environmental impacts of the product procurement and manufacturing process and can provide developers with standardised figures to drastically reduce embodied carbon emissions.

There is now more emphasis than ever on the environmental impacts of a building’s embodied carbon, but the CRE sector’s consistent languor surrounding sustainability has set a dangerous precedent. The clock is ticking, and the simple acknowledgement of problems is no longer enough. Action must be taken to battle embodied carbon’s effects. There is a lot more still to be done in radically altering CRE’s carbon output. Brimstone could be a significant step forward, but we need many more innovations to get on track.

Share your thoughts

No Comments

Sorry, the comment form is closed at this time.